5 gallon filling line

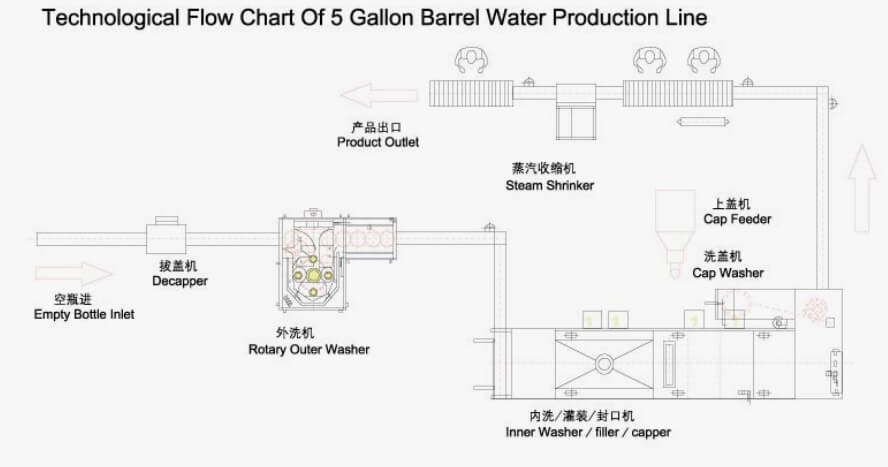

This barrel filling line is specially designed for 5 gallon drinking water production. The whole line consists of decapper, external brushing machine, barrel loader, filling machine, etc. The filling machine is equipped with alkali, disinfectant and water tanks to make sure the recycled barrels sterilized and can be reused, and the machine integrates bottle inner washing, filling and capping into one unit, which is convenient for users to operate the machine. The machine can be semi-auto or full-auto depending on production capacity.