Welcoming distributors and end-users around the world to cooperate with us, we are looking forward to cooperating and getting win-win situation with home and abroad customers.

Lon exchanger is a device commonly used in water treatment at present. It can soften or desalinate water by selecting a certain process. It mainly uses some ion exchangers to temporarily fix the unnecessary ions in the raw water, so that the content of these ions in the water can be reduced to the required level. The ions fixed by the exchanger are released in the regeneration solution, and the exchanger can be used again. That is to say, its essence is the physical and chemical reaction between the insoluble electrolyte (resin) and another electrolyte in the solution, that is, the exchange reaction between the exchangeable ions on the resin and other ions of the same sex in the solution.

As a new technology of separation, concentration, purification and recovery process, electrodialysis is widely used in chemical, pharmaceutical, food and other industries. The application in the food industry mainly focuses on the purification of soda water and beer water, and it is used to soften (desalt) water in soft drink factories. Electrodialysis technology uses an ion exchange membrane with selective permeability and good conductivity. Under the action of an external DC electric field, according to the principle of opposite sex attraction and same sex repulsion, the anions and cations in the raw water pass through the anion exchange membrane and the same sex repulsion respectively. A technology that achieves purification by using cation exchange membranes.

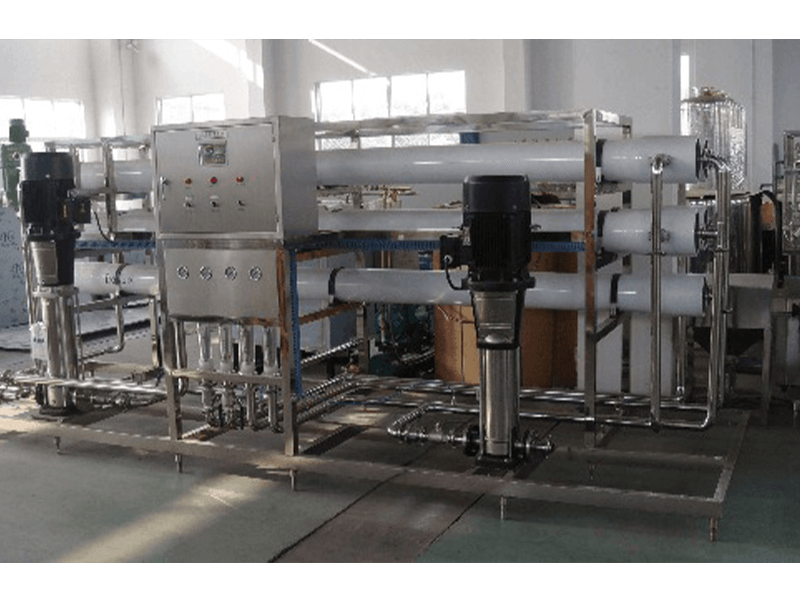

Reverse osmosis is currently a membrane technology with large application scale and relatively mature technology. Its application accounts for about half of the entire membrane separation field, and it is a major breakthrough in the development of membrane technology. Reverse osmosis is the separation of the solvent in the solution through the reverse osmosis membrane. The application of reverse osmosis has developed from seawater desalination, hard water softening, etc. to the concentration of vitamins, antibiotics, hormones, etc., the separation of bacteria and viruses, and the concentration of fruit juice, milk, and coffee. It is widely used. The advantages of reverse osmosis equipment are continuous operation, stable product water quality; no need to regenerate with acid and alkali; no shutdown due to regeneration; saving backwash and cleaning water; producing ultrapure water with high yield (yield can be as high as 95%); regeneration Sewage does not require water treatment facilities; low operating and maintenance costs; simple installation and low cost.

There are two keys to the production of pure water in reverse osmosis facilities: one is a selective membrane, which we call a semi-permeable membrane, and the other is a certain pressure. Simply put, there are many pores on the reverse osmosis semi-permeable membrane. The size of these pores is equivalent to the size of water molecules. Since bacteria, viruses, most organic pollutants and hydrated ions are much larger than water molecules, they cannot pass through. The water phase of the reverse osmosis membrane is separated by passing through the reverse osmosis semi-permeable membrane. Among the many impurities in water, soluble tears are more difficult to remove. Therefore, the water purification effect of reverse osmosis is often determined by the desalination rate of the army. The desalination rate of reverse osmosis is mainly determined by the selectivity of the reverse osmosis semi-permeable membrane. The salt removal rate of the reverse osmosis membrane element with higher selectivity can be as high as 99.7%.

For reverse osmosis separation, a preferential adsorption layer must first be formed at the membrane-solution interface. The degree of preferential adsorption depends on the chemical properties of the solution and the chemical properties of the membrane surface. As long as the appropriate membrane material is selected and the microscopic surface of the membrane is simply changed Pore structure and operating conditions, reverse osmosis technology can be applied to solute separation of any degree of separation.