Welcoming distributors and end-users around the world to cooperate with us, we are looking forward to cooperating and getting win-win situation with home and abroad customers.

When operating the bottle blowing machine, the preform should first be placed in the preform container, and then the conveying device in the machine will automatically enter the automatic positioning device according to the preform, and then the preform mouth will be upward, loaded onto the preform holder and sent to the drying tunnel.

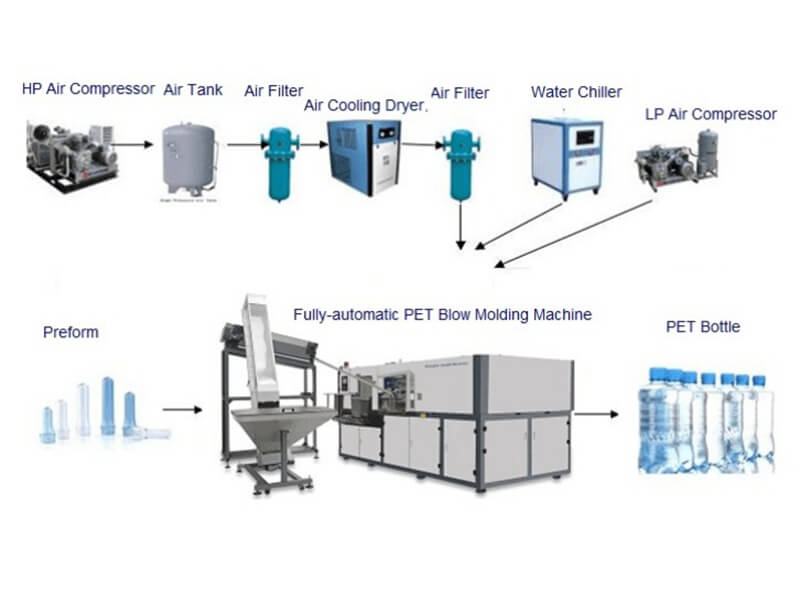

After heating, the preform will be sent to the blowing and drawing platform for mold clamping. After the low-pressure and high-pressure blowing and drawing, the gas will be removed, and the mold will be opened after Z. People can start from the platform of the automatic blow molding machine. Take down the formed bottle.

Mineral water bottle blowing machine is mainly used for blowing mineral water bottles. The bottle brings convenience. The bottle blowing machine is mainly operated by the oil-free airbag clamping technology, which not only has a large clamping force, but also has less force in the toggle operation and long life. When people use the blow molding machine, they should How to operate to make it easier and more convenient to use and prolong the service life of the blow molding machine?

1. When people use the blow molding machine, they should carefully check whether the power supply, control system, heating system, etc. of the blow molding machine are in normal state. normal use and operation of the equipment.

2. When using the blow molding machine, the mold should be accurately installed on the blow molding machine, and it should be carefully checked whether the button is already in the exact position, and it needs to be started, debugged or operated according to the specified requirements. Machines and equipment operate and work under normal conditions.