Welcoming distributors and end-users around the world to cooperate with us, we are looking forward to cooperating and getting win-win situation with home and abroad customers.

DCGF24-24-8 3 in1 filling machine is used to fill carbonated drinks, such as coke, sparking water, etc. Suitbale for capacity of 8000bph

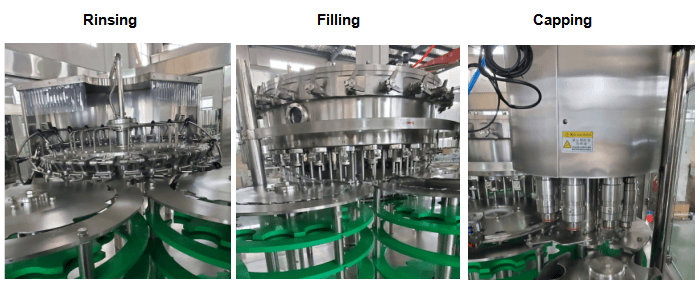

Description:

DCGF Series 3 in1 unit soda drink filling machine is mainly used for filling carbonated beverage such as Coca cola, Pepsi-cola, Sprite drink, The machine is most applied for plastic and glass bottles, it can be easily adjusted to fill various shape and volume of bottles.

Features

1) Using a rotary intermittent spray rinsing method, transferring bottles to the bottle cliping shelves, then invert the bottles and spray bottle until synchronization drained out of the bottle into the filling.

2) Bottles transmission adopt clip bottleneck technology, bottle-shaped transform do not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3) With Japan's Mitsubishi inverter, Mitsubishi programmable logic controller (PLC) control, from the bottle into the machine to automatically control the entire process of packaging. Production capacity can be adjusted according to need, this machine uses frequency conversion, stable and reliable.

4) Adopted by a magnetic clutch screw lid, torque adjustable to ensure capping quality.

5) Where contact with the liquid part are made of high quality stainless steel, in line with food hygiene requirements.

Technical Specification:

Model | DCGF24-24-8 |

Production Capacity (BPH) | 8000(Based on 500ml PET bottle) |

Washing head | 24 |

Filling head | 24 |

Capping head | 8 |

Suitable Bottle Size | Diameter φ50-φ95 V:330-1500mm |

Suitable cap type | Plastic caps |

Filling Precision | ≤5mm liquid level |

Filling type | Balanced pressure filling (Isorbaric) |

Total Power Supply(KW) | 5.5 |

Overall Dimensions(mm) | 3100x2100x2500 |

Weight(KG) | 5000kg |

Components list :

No. | Item | Brand |

1 | PLC | Germany Siemens |

2 | Touch Screen | Taiwan Eview |

3 | Transducer | Germany Siemens |

4 | Main motor | Germany Siemens |

5 | Main Pneumatic Piston | Taiwan AIRTAC |

6 | Small Pneumatic Piston | Taiwan AIRTAC |

7 | Other Pneumatic Elements | Taiwan AIRTAC |

8 | Solenoid Valve | Taiwan AIRTAC |

9 | Relay | French Schneider |

10 | Button | French Schneider |

11 | Air Switch | French Schneider |

12 | Photo Electricity | Japan Omron |

13 | Stainless steel | korea Posco SUS304 |

Model: | DGCF16/12/6 | DGCF18/18/6 | DGCF24/24/8 | DGCF32/32/10 | DGCF40/40/10 | DGCF50/50/12 | DGCF60/60/15 | |||

Production Capacity:500ml(b/h) | 2000-3000 | 3000-4000 | 5000-6000 | 6000-8000 | 10000-12000 | 12000-15000 | 15000-18000 | |||

Filling precision | ≤5mm (liquid level) | |||||||||

Filling pressure(Mpa) | <0.4 | |||||||||

Suitable bottle standard:(mm) | Bottle diameter: φ40-φ80, bottle height: 130-280mm | Bottle diameter: φ50-φ100 bottle height: 150-320mm | Bottle diameter: φ50-φ110 bottle height: 200-380mm | |||||||

Suitable cap standard:(mm) | Plastic screw cap, φ50-φ110 | |||||||||

Pressure for washing bottle(Mpa) | 0.18-0.25 | |||||||||

Water consumption for washing bottle(Kg/h) | 1300 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | |||

Gas source pressure(Mpa) | 0.4 | |||||||||

Gas consumption(m3/min) | 0.3 | 0.4 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | |||

Total power(Kw) | 5.03 | 5.03 | 6.57 | 8.07 | 9.52 | 11.57 | 16.02 | |||

Overall Dimension(L×W×H, mm) | 2100×1500×2200 | 2450×1800×2200 | 2750×2180×2200 | 3600×2200×2200 | 4600x3800x2500 | 5000x4700x2500 | 6500x5400x2500 | |||

Total Weight:(kg) | 2000 | 3500 | 5500 | 8000 | 8500 | 10000 | 12500 | |||