Welcoming distributors and end-users around the world to cooperate with us, we are looking forward to cooperating and getting win-win situation with home and abroad customers.

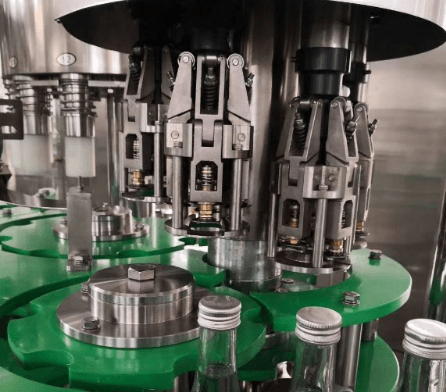

This water filling machine is specially designed for glass bottles with aluminium caps. Different from plastic bottle filling, The bottle rinsing clips adopt food grade enviromental protection plastic material instead of SUS304, and the capping heads is customized for aluminium caps.

This CGF16-12-6 water filling machine is applied for glass bottles with aluminium caps, suitable for small capacity 2000-3000 bottles per hour. The production rate of glass bottle filling is normally smaller than that of PET bottles. To ensure filling stability and high capping quality, bottle holders added and customzied capping head adopted.

Filling Heads

Capping heads

Finish Goods

Technical Specification:

Model | CGF16-12-6 |

Production Capacity (BPH) | 2000-3000(Based on 500ml glass bottle) |

Washing head | 16 |

Filling head | 12 |

Capping head | 6 |

Suitable Bottle Size | Diameter φ50-φ95 V:330-1500mm |

Suitable cap type | Plastic caps(cheaper) / Aluminium caps |

Filling Precision | ≤5mm liquid level |

Total Power Supply(KW) | 5.5 |

Overall Dimensions(mm) | 2400x1800x2200 |

Weight(KG) | 2800kg |

Components lists :

No. | Item | Brand |

1 | PLC | Japan MITSUBISHI |

2 | Touch Screen | Taiwan Eview |

3 | Transducer | Japan MITSUBISHI |

4 | Main motor | Germany Siemens |

5 | Main Pneumatic Piston | Taiwan AIRTAC |

6 | Small Pneumatic Piston | Taiwan AIRTAC |

7 | Other Pneumatic Elements | Taiwan AIRTAC |

8 | Solenoid Valve | Taiwan AIRTAC |

9 | Relay | French Schneider |

10 | Button | French Schneider |

11 | Air Switch | French Schneider |

12 | Photo Electricity | Korea Autonics |

13 | Stainless steel | korea Posco SUS304 |

Model | CGF8-8-3 | CGF16-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-12 | CFG60-60-15 |

Heand of washing,filling capping | 8-8-3 | 16-12-6 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 | 60-60-15 |

Production capacity:500ml (BPH) | 2000 | 4000 | 6000 | 10000 | 12000 | 16000 | 22000 | 26000 |

Bottle Size | Φ=50-Φ95mm 330-1500ml | Φ=50-105mm 330-2250ml | Φ=50-110mm 330-2500ml | |||||

Pressure(Mpa) | 0.25-0.3 | |||||||

Power(kw) | 3.8 | 5.8 | 6.6 | 7 | 10.4 | 11.5 | 14 | 19 |

Overall Dimension(mm) | 2200x1600x2500 | 2300x1700 x2500 | 2500x1850 x2500 | 3100x2100 x2500 | 4600x2160 x2500 | 4600x3800 x2500 | 5000x4700 x2500 | 6500x5400 x2500 |

Weight(kg) | 2000 | 2600 | 3500 | 5000 | 6800 | 8500 | 10000 | 12500 |

1. Q: Are you a manufacturer or trading company?

A: We are a manufacturer which have 20-years experience in beverage machinery. We are willing to help our clients with our expertise, and welcome any potential clent to visit our factory.

2. Q: How long is the delivery time?

A: Normally, it will take 30-45 days for production, but the situation may vary upon clients’ final order and when we receive bottle and cap samples. Some machine with very large production capacity may need longer time to delivery.

3. Q: What is your payment term?

A:30-40% T/T as deposit before production, and the balance should be paid before shipment. Regarding any separate purchase of machine fittings and any moulds, 100% full payment is required.

4. Q: How do you pack before shipping?

A: Regarding packing material, we first wrap the machines with PE protection film and coated with wooden case outside. All the wooden board we used have already passed fumigation procedure, which is safe and satisfies exporting condition.

5. Q: How long is your warranty? And what kind of after-services do you provide?

A: We offer one year warranty for main parts, and we will provide customers with some cosumable parts for free when shipping. Within the year of warranty, clients can ask for after-services: free spare parts for machine self problem, online support, field maintenance. We can also send our engineer to clients’ country to help commissioning, but due to coronavirus, the oversea business trip has been suspended temporarily .

6. Q: Do you provide any customized service?

A: Of course, our products are essentially custom-made as the machine should be designed to fit in different customers’ bottle samples and capacity. We can also make customized logos according to clients’ requests. We will give clients professional suggestions to help them get the most suitable machines.

7. Q: What kind of information you have to know before quotation?

A: Clients should first tell us what kind of filling liquid and required production capacity, and if they need a single filling machine or a complete filling line. Also, how many bottle samples, PET bottle or glass bottle; it’s better if customers can show us their bottle sample.