Welcoming distributors and end-users around the world to cooperate with us, we are looking forward to cooperating and getting win-win situation with home and abroad customers.

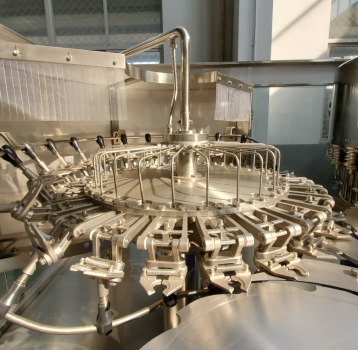

CGF series filling machine is suitable for no gas contained liquids, such as pure drinking water and mineral water. The machine is full-automatic in washing, filling and capping. Can be applied to 200-2000ml PET bottles.

Rinsing

Filling

Capping

CGF series machine is a kind of professional monoblock filling and sealing machine for mineral/ pure water and other non-gas beverages. It is multifunctional which washing, filling and capping are combined in a single machine, so it is also called 3 in 1 machine. It has the feature of compact structure, ease of operation and high automation and stability. Frame and main parts are made by SUS304 material.

Features

1. The whole machine adopts stuck bottleneck suspension operation , so the bottles can be stable and reliable under high-speed operation. Meanwhile, the number of change moulds is greatly reduced, which is more convenient and faster when changing the bottle type.

2. Using stainless steel flip bottle clamp that allow the clamp not to contact the upper part of the bottle mouth thread, and a spray head is provided so that the inner wall of the bottle can be rinsed fully.

3. Adopting advanced gravity filling principle, the filling is fast, stable, and accurate.

4. The whole machine adopts man-machine interface touch screen buttons, PLC computer control, and is equipped with a cover missing and overload protection alarm device, which can find and eliminate faults in time and have a high automation.

5. The parts in contact with water are made of high-quality 304 stainless steel, and the main electrical components are all products of well-known international manufacturers.

Specification:

Model | CGF24-24-8 |

Production Capacity (BPH) | 8000-10000BPH (Based on 500ml PET bottle) |

Washing Head | 24 |

Filling Head | 24 |

Capping Head | 8 |

Applicable Drink | Pure Water /Mineral Water |

Suitable Bottle Size | Diameter: φ50-φ100mm, Volume:500ml-1500ml |

Suitable Cap Type | Plastic Screw Cap |

Filling Precision | ≤5mm Liquid Level |

Power Supply | AC 220/380V 50HZ |

Bottle Washing Filling Pressure | ≥0.3Mpa |

Working Air Pressure | 0.2-0.3Mpa |

Air Consumption | 0.8/m³/Min |

Total Power Supply(KW) | 7kw |

Overall Dimensions(mm) | 3100x2100x2500mm |

Weight(KG) | 5000kg |

Components Lists:

No. | Item | Brand |

1 | PLC | MITSUBISHI |

2 | Touch Screen | TAIMAN WEILUN |

3 | Frequency Converter | MITSUBISHI |

5 | Main Motor | Siemens |

6 | Air Cylinder | Taiwan AIRTAC |

7 | Main Pneumatic Piston | Taiwan AIRTAC |

8 | Small Pneumatic Piston | Taiwan AIRTAC |

9 | Other Pneumatic Elements | Taiwan AIRTAC |

10 | Solenoid Valve | Taiwan AIRTAC |

11 | Pump | LingXiao/NanFang |

12 | Control System | French Schneider |

13 | Intermediate Relay | French Schneider |

Water Filling Machine

Model | CGF8-8-3 | CGF16-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-12 | CFG60-60-15 |

Heand of washing,filling capping | 8-8-3 | 16-12-6 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 | 60-60-15 |

Production capacity:500ml (BPH) | 2000 | 4000 | 6000 | 10000 | 12000 | 16000 | 22000 | 26000 |

Bottle Size | Φ=50-Φ95mm 330-1500ml | Φ=50-105mm 330-2250ml | Φ=50-110mm 330-2500ml | |||||

0.25-0.3 | ||||||||

Power(kw) | 3.8 | 5.8 | 6.6 | 7 | 10.4 | 11.5 | 14 | 19 |

Overall Dimension(mm) | 2200x1600x2500 | 2300x1700 x2500 | 2500x1850 x2500 | 3100x2100 x2500 | 4600x2160 x2500 | 4600x3800 x2500 | 5000x4700 x2500 | 6500x5400 x2500 |

Weight(kg) | 2000 | 2600 | 3500 | 5000 | 6800 | 8500 | 10000 | 12500 |

FAQ

1. Q: Are you a manufacturer or trading company?

A: We are a manufacturer which have 20-years experience in beverage machinery. We are willing to help our clients with our expertise, and welcome any potential clent to visit our factory.

2. Q: How long is the delivery time?

A: Normally, it will take 30-45 days for production, but the situation may vary upon clients’ final order and when we receive bottle and cap samples. Some machine with very large production capacity may need longer time to delivery.

3. Q: What is your payment term?

A:30-40% T/T as deposit before production, and the balance should be paid before shipment. Regarding any separate purchase of machine fittings and any moulds, 100% full payment is required.

4. Q: How do you pack before shipping?

A: Regarding packing material, we first wrap the machines with PE protection film and coated with wooden case outside. All the wooden board we used have already passed fumigation procedure, which is safe and satisfies exporting condition.

5. Q: How long is your warranty? And what kind of after-services do you provide?

A: We offer one year warranty for main parts, and we will provide customers with some cosumable parts for free when shipping. Within the year of warranty, clients can ask for after-services: free spare parts for machine self problem, online support, field maintenance. We can also send our engineer to clients’country to help commissioning, but due to coronavirus, the oversea business trip has been suspended temporarily .

6. Q: Do you provide any customized service?

A: Of course, our products are essentially custom-made as the machine should be designed to fit in different customers’ bottle samples and capacity. We can also make customized logos according to clients’ requests. We will give clients professional suggestions to help them get the most suitable machines.

7. Q: What kind of information you have to know before quotation?

A: Clients should first tell us what kind of filling liquid and required production capacity, and if they need a single filling machine or a complete filling line. Also, how many bottle samples, PET bottle or glass bottle; it’s better if customers can show us their bottle sample.