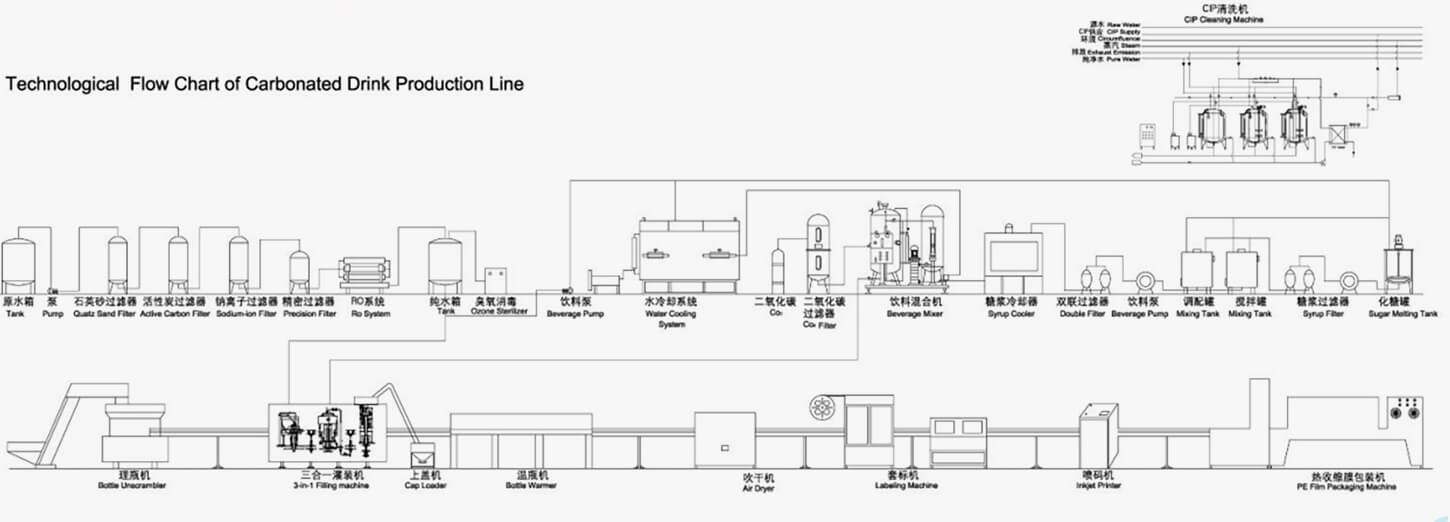

CSD filling line

This DCGF series rotary machine is specially designed for carbonated drinks,

such as coca cola, pepsi, soda

water, etc. It contains automatic bottle washer, bottle filler, bottle capper.

This DCGF series rotary machine is specially designed for carbonated drinks,

such as coca cola, pepsi, soda

water, etc. It contains automatic bottle washer, bottle filler, bottle capper.

The whole filling line is suitable for same bottle diameter different bottle height, easy to adjust. When with different bottle diameter, only needs to set with some extra bottle change parts to share, easy to change.

The machine is made of the high quality of SUS304 material, meet with GMP standard, has long lifespan.

The machine is automatic with electromagnetic speed-regulator, speed adjustable, and where contact with the liquid part are made of stainless steel (SUS304 or SL316), in line with food hygiene requirements.

Bottles transmission adopt clip bottleneck technology, bottle-shaped transform do not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

Super-low star wheel structure can highly improve the strength of the whole machine. adopts advanced PLC automatic control technology, the key electrical components from famous company such as Mitsubishi, France Schneider, OMRON,etc.

Adopts magnetic clutch screw capping system, torque adjustable to ensure capping quality.

The value proposition of the company is professional technical plan, high product quality, and prompt after-sale service, which makes the company form specific advantages over market competitions.

Blending tanks are generally used tank equipment on beverage production lines. The production needs of beverages are blended and mixed. Therefore, there will be a blending system on the beverage production line, and the blending tank is the primary equipment in the blending system.

The three-in-one bottle of mineral water filling machine is a rotary rinser, which is mainly used for rinsing new bottles of beverages, water and other products. The bottle is then sent to the filling machine for filling of the product.

The development of the three-in-one filling machine industry depends on the development of the filling industry. The three-in-one filling machine industry still has great potential for development.Recently,Domestic production enterprises have been actively improved their technical level.

In the market of three-in-one filling machine barreled water filling machine, the technology of three-in-one filling machine barreled water filling machine is closely following the changes of customer needs, and customer demand is the main driving force for market development.